Thirty CrillEye modules installed worldwide

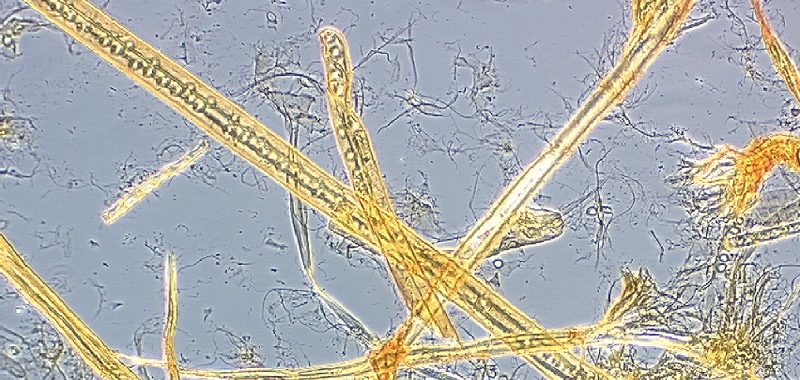

Since the first installation in 2013 PulpEye has now installed thirty CrillEye online analysers worldwide. The technology, developed in cooperation with Innventia, makes it possible to measure the amount of crill and hence to calculate and control tensile, tear, burst, Scott Bond, z-strength bulk, and density in combination with fibre data. Crill consists of fibrils […]

PulpEye analyser successfully in operation at Millar Western Whitecourt

The Canadian BCTMP and lumber producer Millar Western has installed a PulpEye system to its Whitecourt pulp mill. The delivery consists of analyser modules for CSF, fibre dimensions, shives, brightness and crill. This is the ninth PulpEye installation in Canada showing that PulpEye technology is well established in the Canadian pulp industry. Millar Western’s Whitecourt […]

Press Release Major PulpEye order from Iggesund

PulpEye received its second biggest order ever when Iggesund paperboard bought two complete PulpEye sets, one for the unbleached and one for the bleached pulps. Both PulpEye cabinets are equipped with modules for online analysis of kappa number, brightness, fibre, shives and fibre wall thickness as well as the dot analyser DotEye. The order also […]

Cartulinas CMPC Maule first to buy PulpEye in Chile

The Chilean folding boxboard maker Cartulinas CMPC S.A has bought two PulpEye online analyser systems to its mill in Maule, one of the world’s biggest folding boxboard mills. This is the first PulpEye order to Chile. One system will be installed in the BTMP pulp mill and the other in the board mill’s stock preparation. […]PulpEye No. 50 bought by Ahlstrom-Munksjö Aspa Bruk

PulpEye has now reached the milepost of 50 units sold as Ahlstrom-Munksjö Aspa Bruk in Sweden invests in a PulpEye system for pulp analyses online. Bleached and unbleached kraft pulp is produced at the Aspa mill and the PulpEye they have acquired contains modules for determination and measuring of kappa number, brightness, dots and pH. […]Press Release: PulpEye has delivered DDA No. 100

Solenis LLC recently purchased Dynamic Drainage Analyzer (DDA) No. 100 from PulpEye. The DDA is a dynamic drainage tester which gives drainage values comparable to drainage in a wire section. The tester is used by paper and board producers as well as chemical and filler suppliers around the world. With the aid of the DDA, […]PulpEye introduces online measurement of fibre wall thickness

A successful cooperation between FPInnovations, Canfor and PulpEye has resulted in the world’s first technology for measurement of fibre wall thickness. As the first pulp producer in the world, Canfor has installed the fibre wall thickness module, FWT, in four PulpEye units in their pulp mills. FPInnovations has patented* a technology for determining fibre wall […]